Tool Room Lubricants

Tool Room Lubricants Supplier

Tool Room Lubricants are developed from highly refined base stocks with superb oxidation stability and contain oiliness, anti-wear, non-drip, and anti-foam additives. These combinations allow the products to carry excessive load of machine tools with base stick-slip, chatter, and improved surface finish to the job. These oils also prevent the parts against rust and corrosion which decrease the consumption of oils. If applied perfectly, hydraulic oils save energy, reduce machine and component wear, hence, extend maintenance intervals and increase the life of machine.

Features of Tool Room Lubricants :

- Low power consumption

- Superior oxidation stability

- Anti-wearing & Durable

- Cost effective & Long life

Advantages of Tool Room Lubricants :

-

- It gives protection against corrosion and rust because hydraulic oils are hydrolytically stable.

- The viscosity stability of oils helps in optimal operations even under extreme working temperatures and conditions.

- It gives protection from foaming and formation of sludge and deposits due to which system’s efficiency, reliability, and performance are increased.

- It helps in protecting the hydraulic system when exposed to air and water which means that hydraulic oils possess anti-oxidation properties.

- Filters of hydraulic systems maintain their filtration efficiency as these oils are serve as contaminants eliminators.

- It has as a demulsibility property where Hydraulic equipment is protected against water emulsion as the oil quickly separates water and prevents damage from occurring.

- It gives protection against wear and tear which results in an extended life cycle of the equipment and hydraulic machinery

Tool Room Lubricants Latest Price

| Tool Room Lubricants Latest Price: |

*Prices shown above are provisional prices and may change due to different market conditions for latest prices please Contact Us at +91 9820229229 or send an enquiry through the Enquiry Form to get the final price within hours. DNR Corporation is one of the most competitive suppliers of Chemical products from India and our prices are very competitive. Please request the updated price list and ready stock information along with your requirement.

Specifications / Technical Parameters of Tool Room Lubricants

Industrial applications / Uses of Tool Room Lubricants

- Tool Room Lubricants is used in Metal cutting machinery & Metal Fabrication

- Tool Room Lubricants is used in Agriculture & Food Environment technology

- Tool Room Lubricants is used in Construction industry

- Tool Room Lubricants is used in Mining, Ship Building, and Steel Industry

- Tool Room Lubricants is used in Aviation, Aerospace industry

- Tool Room Lubricants is used in Various Chemical & Medicine Industry

Related Search Tags : Tool Room Lubricants manufacturer near mumbai, maharashtra, Tool Room Lubricants manufacturers in india, Tool Room Lubricants price

Why DNR Corporation?

We offer the most qualitative products extending our services in the international arena, we stand apart from the other competitors as we have:

- Superior Performance Products.

- Rich industrial experience of more than 27 years.

- Specialist in synthetic technology Oils & Fluids.

- Ethical and valued business operations.

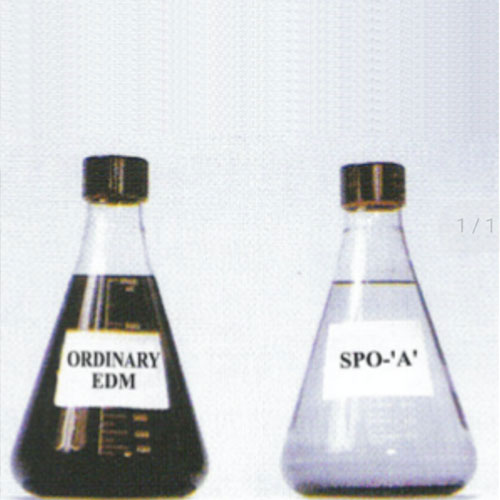

Since our inception in 1993, DNR Corporation is one of the leading manufacturers, suppliers, exporter, stockist and dealer of specialty products a wide range of synthetic technology all our oils such as EDM Oils, CNC VMC cutting oils, metal working fluids, neat cut oils, Gun drill oils, EP000 greases and slideway lubricating oils, a wide array of EDM Oils. Our offered range of products is inclusive of our specialty range Cutting Oil, Hydraulic Oil and EDM Oil. DNR Corporation is committed to customer fulfilment by delivering the best quality chemical products at competitive market prices.

Industries We Serve

| Automotive Industries | Rubber industry | Hydraulic Systems Manufacturing |

| Construction Industry | Metal Cutting & Drilling | Textile Industries |

| Heavy Machineries | Petroleum Industries | Power Transmission |

Market Area

DNR Corporation supplying to these Indian Cities.

Pune| Mumbai| Ahmedabad| Bengaluru| Chennai| Delhi| Kolkata| Hyderabad| Agra| Ajmer| Aligarh| Amravati| Amritsar| Asansol| Aurangabad| Bareilly| Belgaum| Bhavnagar| Bhiwandi| Bhopal| Bhubaneswar| Bikaner| Bilaspur| Bokaro Steel City| Chandigarh| Coimbatore| Cuttack| Dehradun| Dhanbad| Bhilai| Durgapur| Erode| Faridabad| Firozabad| Ghaziabad| Gorakhpur| Gulbarga| Guntur| Gwalior| Gurugram| Guwahati| Hamirpur| Hubli–Dharwad| Indore| Jabalpur| Jaipur| Jalandhar| Jalgaon| Jammu| Jamnagar| Jamshedpur| Jhansi| Jodhpur| Kakinada| Kannur| Kanpur| Karnal| Kochi| Kolhapur| Kollam| Kozhikode| Kurnool| Ludhiana| Lucknow| Madurai| Malappuram| Mathura| Mangalore| Meerut| Moradabad| Mysore| Nagpur| Nanded| Nashik| Nellore| Noida| Patna| Puducherry| Purulia| Prayagraj| Raipur| Rajkot| Rajamahendravaram| Ranchi| Rourkela| Ratlam| Salem| Sangli| Shimla| Siliguri| Solapur| Srinagar| Surat| Thanjavur| Thiruvananthapuram| Thrissur| Tiruchirappalli| Tirunelveli| Tiruvannamalai| Ujjain| Vijayapura| Vadodara| Varanasi| Vasai-Virar City| Vijayawada| Visakhapatnam| Vellore| Warangal